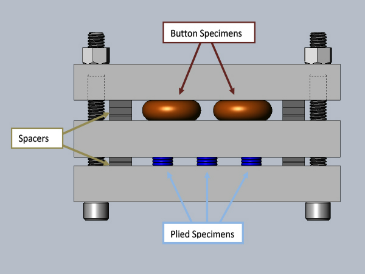

Compresion Set Tester

Compression set tests are intended to measure the ability of rubber compounds to retain elastic properties after prolonged action of compressive stresses. The actual stressing service may involve the maintenance of a definite deflection, the constant application of a known force, or the rapidly repeated deformation and recovery resulting from intermittent compressive forces. Though the latter dynamic stressing, like the others, produces compression set, its effects as a whole are simulated more closely by compression flexing or hysteresis tests. Therefore, compression set tests are considered to be mainly applicable to service conditions involving static stresses. Tests are frequently conducted at elevated temperatures.

Abrasion Resistance Tester

Abrasion resistance is a performance factor of paramount importance for many rubber products, such as tires, conveyor belts, power transmission belts, hoses, footwear, and floor covering. A test capable of measuring resistance to abrasion of rubber, including uniformity of wear behavior under abrasive/frictional service conditions is therefore highly desirable. This test method may be used to estimate the relative abrasion resistance of different rubbers. Since conditions of abrasive wear in service are complex and vary widely, no direct correlation between this accelerated test and actual performance can be assumed. This test method is suitable for comparative testing, quality control, specification compliance testing, referee purposes, and research and development work.

Rheometer

The stiffness of the specimen compound increases when cross links are formed during cure. The direct Proportionately posited between the shear modulus and the cross linking density is based on the statistical theory of rubber elasticity .At a constant temperature of the test, a cross linking isotherm is the function of time of that property which serves to measure the course of the cross linking reaction. In the context of Rheometer, the cross linking isotherm is thus the function of time, of the oscillating shear force F, or of the Rheometer indication proportional to it, occurring at a given temperature as a result of vulcanization. A plot of this torque (force) value against time gives a typical graph called "Cure Curve or Rheograph". A trained eye can monitor the initial trough i.e. processing behavior of the compound, the slope of rise during cure phase i.e. curing characteristics and final shape of the curve. Internationally designated parameters like MI, MH, TS2, TS5, TC50, TC90 etc. are markers which can be used to describe a graph. The Cure Curve obtained with Rheometer is a finger print of compound's vulcanization & processing character

Universal Tensile Test

All materials and products covered by these test methods must withstand tensile forces for adequate performance in certain applications. These test methods allow for the measurement of such tensile properties. However, tensile properties alone may not directly relate to the total end use performance of the product because of the wide range of potential performance requirements in actual use. Tensile properties depend both on the material and the conditions of test (extension rate, temperature, humidity, specimen geometry, pretest conditioning, etc.); therefore materials should be compared only when tested under the same conditions. Temperature and rate of extension may have substantial effects on tensile properties and therefore should be controlled. These effects will vary depending on the type of material being tested. Tensile set represents residual deformation which is partly permanent and partly recoverable after stretching and retraction. For this reason, the periods of extension and recovery (and other conditions of test) must be controlled to obtain comparable results.